Simulation, both in training and clinical practice, has become an increasingly important facet of a surgeon’s life. The escalating costs of cadaveric material makes synthetic alternatives an attractive proposition but, up until recently, these artificial versions have lacked the material properties to make them good cadaveric alternatives. In this interview, Chris Coulson talks to Felix Antenbrink from PHACON and Peter Smith from Axis Medical about 3D printing and the evolution of simulation training.

Felix, thanks for agreeing to do this interview. Can you first of all tell us about yourself and how you came to working for PHACON?

Hello Chris. I grew up in Cologne, Germany and started my education in the Netherlands studying product design. I have a big medical background in my family; my grandfather and uncle were surgeons in Munich and Koblenz. My Grandma from my mother’s side was a nurse in the neurosurgery department at the University Hospital in Essen. During my studies, I was dealing a lot with 3D printing technology and later with PHACON I had the chance to combine my design background with my early childhood fascination for anatomy.

How did the your company, Phacon, start? What are its aims?

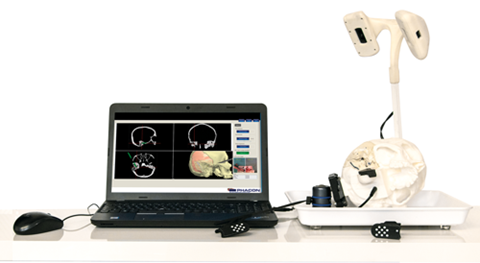

This year PHACON is celebrating its 10-year anniversary. The company was founded in Leipzig, Saxony, a very innovative part of Germany. The founder is a medical engineer and had the idea to create an artificial temporal bone model with electronic detection of risk structures as the facial nerve, dura and sigmoid sinus. The CT-data based temporal should be helpful for the training of young doctors mastering the challenges of temporal bone surgery and especially cochlear implant (CI) surgery. The company’s aim is to change the methods of education with the usage of new technologies, such as 3D printing, finding a supplement to the golden standard of using human specimens.

How do the PHACON products help ENT surgeons?

Human specimens are not always available for all hospitals and surgeons. Storage and handling is often difficult and expensive. Both the availability and price are reasons why many hospitals can only train on cadavers on a small scale. Our artificial ENT models are always available and price-effective. Since they are based on CT scans of real patients, we can develop pathologies and even paediatric anatomies. This is, for example, interesting for cochlear implant surgery. CI surgery is nowadays done at a very early age; sometimes as young as six months.

“The CT-data based temporal should be helpful for the training of young doctors mastering the challenges of temporal bone surgery and especially cochlear implant (CI) surgery.”

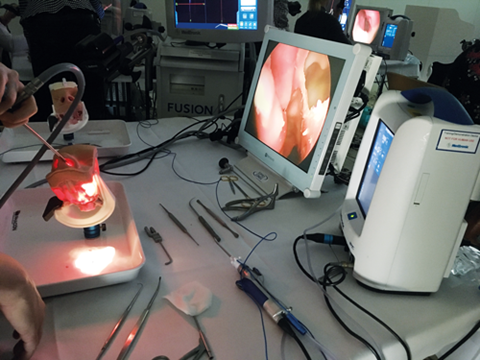

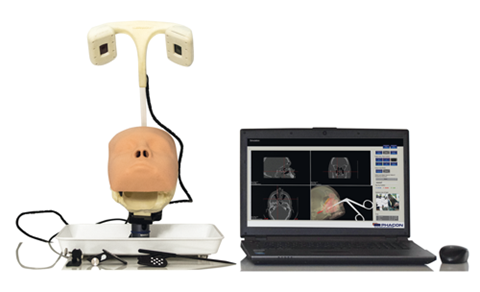

There is no way to train for this besides on our artificial temporal bones. Also, for FESS surgery, our models are a great supplement or alternative for working on human specimens. With the PHACON Trainers the doctors have the chance to work on realistic anatomical models of a bone like material combined with various soft tissues. They can use their common devices and instruments and with the navigation camera and software they can navigate within the included CT data set of the related model. Inside the software you can later evaluate your training. These features create a comprehensive training environment independent from location. No wet lab is needed and you can train in almost any location.

Rhinoplasty course. Dr Maas, Kassel, Germany, 2017.

Predrilled temporal bone facial recess, round window.

What is the development process of PHACON products?

The basis of all of our work is CT or MRI data. We segment the parts that we would like to develop and print. We then convert the segmented data, which is still 2D, into a 3D virtual model then further process this model on the computer to be able to print it in different parts.

The model consists of many different parts since we have to add various structures; for example, nerves and vessels of a different material, such as soft tissue.

The parts are later assembled by hand - this is a very skilful job which requires a lot of precision.

FESS and rhinoplasty course. Dr Olsson Ystad, Sweden, 2017.

Wow, so do you print the temporal bone structure then add in the nerves, tympanic membrane and dura after by hand? Do you think these structures will be 3D printable soon?

Yes, we print only the bony parts and add all other structures later by hand before we assemble the bone. It is possible to print in many different techniques nowadays, even some softer materials. But you can only print one material in each 3D printer. Even if you do print them, you would need to assemble the different printed materials later to create one complete, detailed model with all the structures and tissues.

Are the scans that are used to make the models standard CTs? Or do they need a far greater dosage to generate the resolution needed for printing? If they are standard CTs, do you envisage a time when surgeons can practise particular difficult operations preoperatively?

The CTs PHACON uses are standard CTs. What is important is the slice distance of about 1mm for detailed models. For some of the preoperative models, a slice distance of 3mm is enough. In general, you can say the thinner the slice distance, and better the resolution, the better the detailed model.

We already prepare preoperative models, for example, for cranio-maxillary facial models PHACON works together with different hospitals that send us CTs of their patient cases, then we create their individual patient model and send it within 24 hours. This is an important service we provide to give the doctor an exact model of the patient’s case. We can also print tumour structures in different colours to have it clearly visible. When doctors have to implant bone material of the patient’s leg, for example, to place it into the jaw bone, they ask for models of the leg bone and the jawbone and, before the surgery, they practise how the pieces would fit together best.

Are there any new products PHACON are currently working on, ideally letting us know about any you are keeping secret?

We are always working on different new developments. Some are customised solutions for the big instrument manufacturers. We are also working on new models for our own portfolio.

We have just finished the development of our extended patient “Schmidt” with a very detailed middle ear in which stapes and incus are connected in a new way, to give them the exact flexibility they have in real life. This is important to train in middle ear surgery, especially the placement of middle ear implants. Besides we finished a new model of a lower jaw bone for the training of placing dental implants. This model is based on a real case and the surgery of the case can be repeated in training courses.

What do you think your company’s biggest product will be in 15 years’ time?

Our aim is to establish a standard in surgical education. Every surgeon should train on the PHACON Trainers and models to improve their skills. We will have a wider portfolio and probably add more medical disciplines to our portfolio.

Besides our key field of ENT, we already work in implantology and spine. We will work deeper in neuro and orthopaedic surgery. Of course, we will constantly further develop our key discipline of ENT.

Innovating in this area must be extremely challenging, what do you do to relax?

I like to enjoy my private time. I like cooking, reading and meeting friends. I still do drawing and sketching when I find the time. I like culture; visiting museums and art exhibitions. There are many here in Leipzig and there is a very colourful, and young art scene. To relax my mind, I also run and do Taekwondo.

Here is what Peter Smith had to say…

Peter, thank you for taking the time to answer some questions. Tell us, why did you wish to back PHACON and what attracted you to being a distributor?

Axis Medical attends many temporal bone workshops, as we distribute ossicular and stapes prostheses from Grace Medical, and so I was aware of the issues surrounding the acquisition of temporal bone specimens, and the requirement for them to be used on licensed premises. It seemed to me that the provision of artificial bones could be helpful in this situation.

What do you feel is unique about PHACON’s products?

I had previously used other artificial bones to help demonstrate otology products, but what differentiated the PHACON bones was their detailed anatomical accuracy, manufactured as they are from actual human CT scans. Prior to commencing distribution, I sought and obtained confirmation from otologists that the bones were indeed accurate representations, not only anatomically, but also in the way that they behaved when drilled. Another attraction was the supply of paediatric, as well as adult, bones – unlikely to be available as human specimens.

In your opinion how will PHACON’S products change the training landscape?

I believe that the availability of the PHACON bones, with or without the navigation system, can transform the training landscape, making the provision of training simpler and potentially more effective.

PHACON Temporal Bone Trainer.

PHACON Sinus Trainer.

PHACON Sinus Trainer.

‘Spotlight on Innovation’ is an informative section to provide insight and discussion on recent advances in technology and research and does not imply endorsement by ENT and Audiology News.