The traditional approach to managing workplace noise has failed - how can we better protect our nation’s hearing using smart hearing protection?

Occupational noise-induced hearing loss (ONIHL) is the most common occupational health condition in the world and the most commonly reported occupational disease in Europe [1]. It is estimated that nearly two million of the 12 million UK adults suffering from hearing loss have had their hearing damaged due to noise exposure at work [2].

With more than 2.3 million Britons still working in harmful levels of noise [3], the number of people presenting to clinics with preventable ONIHL and tinnitus is set to rise, unless we take a new approach to managing workplace noise.

Having practised as a clinical and research audiologist, completed a PhD in Auditory Neuroscience at the UCL Ear Institute and built a hearing conservation company, I have seen first-hand both the cause and effect of ONIHL and tinnitus. Noise control and hearing conservation efforts that I observe in many workplaces today are much the same as those documented over a century ago; in particular, the practice of ineffectually stuffing pieces of foam, paper, wax or cotton into the ear canals in an attempt to protect hearing from noise. I am no longer surprised by the rates of tinnitus and ONIHL that I see, but I am driven to share some simple yet fundamental changes to hearing conservation and noise control programmes that can immediately reduce the risks of both of these insidious, preventable diseases.

“Noise control and hearing conservation efforts that I observe in many workplaces today are much the same as those documented over a century ago”

The primary goal of managing workplace noise is to reduce the risk of ONIHL and tinnitus. Within the realms of what is reasonable and practicable, everything in a hearing conservation and noise control programme should be geared towards reducing this risk. A traditional approach will typically involve some combination of using a noise level meter, dosimeters, noise reports, health surveillance, the hierarchy of controls, regulatory compliance and hearing protection. Each component taken independently has a useful and specific application in the field of noise control but, when brought together as part of a hearing conservation programme, the result is sadly and consistently ineffective. Ultimately and inadvertently, duty holders implement a programme of activities that actually becomes the major underlying cause of the high rates of noise exposure, ONIHL and tinnitus that we see today.

How is this possible? No single element in a noise control or hearing conservation programme is perfect, so the programme needs layers of protection. What we find, however, is that many organisations go through a tick-box exercise of noise control and end up simply providing hearing protection. This results in a single point of failure for the whole programme - if the protection is not worn correctly >95% of the time, the resulting noise exposure means that the protection may as well have not been worn at all. Yet the duty holder and workers will be operating with a false sense of security that they have done what is necessary to prevent harmful exposures when the risks in fact remain high. Where there should be layers of protection that are fail-safe and enable duty holders to design out the noise hazard over time, we instead have a series of activities that are repeated periodically without the ability to make a meaningful reduction to the risk of exposure.

These typical activities and their pitfalls are:

- Measuring and recording noise on site using a noise level meter that provides only an isolated snapshot of noise levels irrespective of the day-to-day reality.

- Using dosimeters to understand noise exposure that does not account for noise dose at the ear and so does not reflect a meaningful dose or exposure risk assessment.

- Producing a noise report that is typically not comprehensible for a duty holder for purposes of risk reduction, resulting in it being filed away and ignored.

- Health surveillance that typically consists of performing audiometry which, by itself, is not sensitive enough to detect the effects of noise exposure as a preventative measure for ONIHL and tinnitus. ONIHL may only show up on an audiogram after the person has already been suffering from tinnitus and communication-in-noise difficulties.

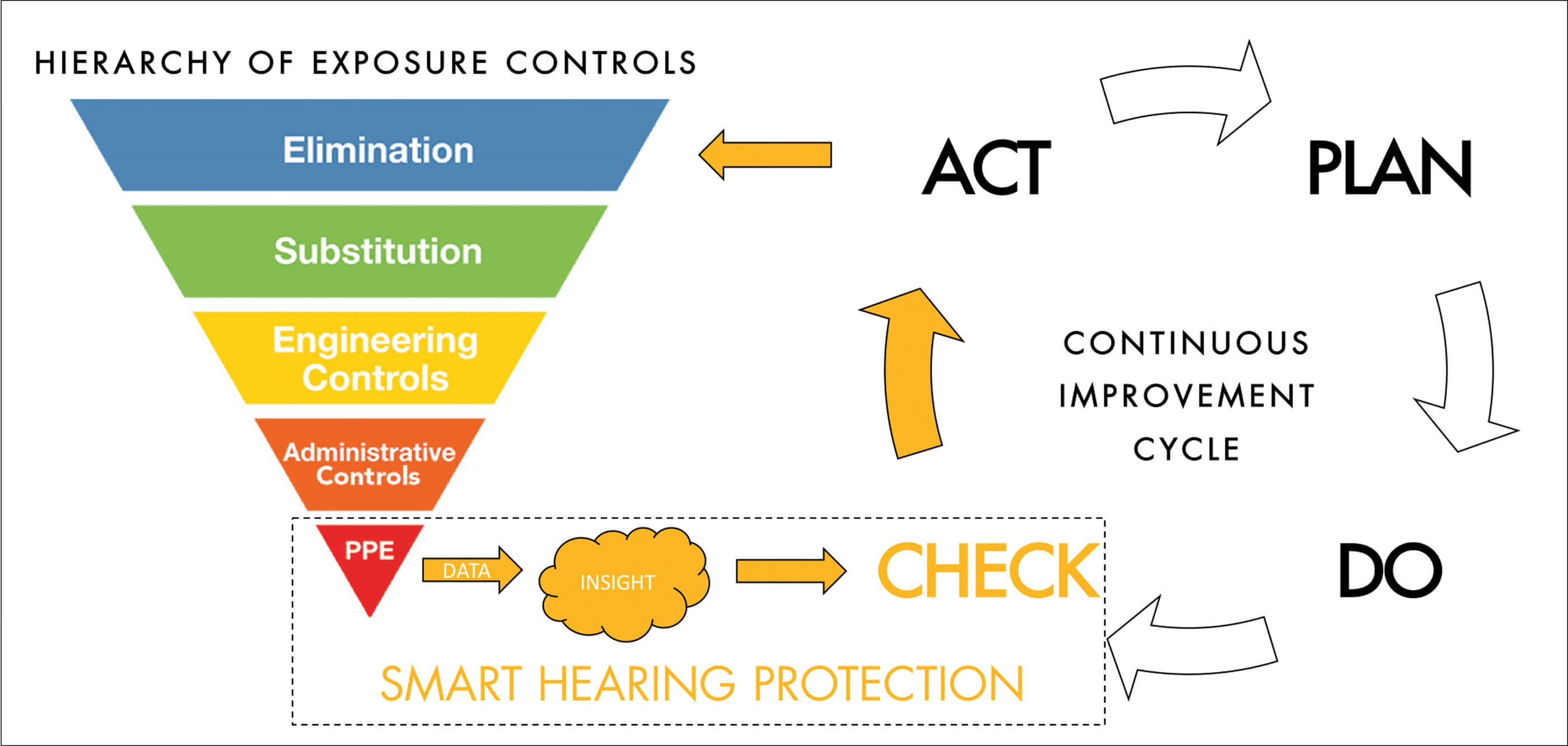

- Applying the hierarchy of controls as a one-off exercise in risk control at the start of a noisy project, in isolation of the need for continuous improvement. This means the day-to-day changes in exposure are not accounted for or mitigated.

- Relying on the control of noise at work regulations (2005) [3] which are not widely enforced due to capacity challenges of enforcement officers. This has resulted in complacency and falling standards in noise control, increasing the risks of noise exposure. The legal requirements are unfortunately also widely treated as the benchmark for best practice rather than as the baseline for good practice.

- Relying on conventional hearing protection such as foam earplugs and passive earmuffs as both the first and last line of defence. This is especially risky when combined with assumed protection levels and the poor wear rates of traditional protection.

Having spent time in noisy workplaces and speaking extensively with duty holders, I have concluded that a disproportionate amount of the noise exposure, ONIHL and tinnitus issues that exist today are due to failings of the last line of defence – the conventional hearing protection. When fitted correctly, these options block out sound indiscriminately, reducing the user’s situational awareness, ability to communicate and to hear important sounds. The result is that wearers do not wear the protection correctly and duty holders have no reasonable way of being made aware of this.

“If the protection is not worn correctly >95% of the time, the resulting noise exposure means that the protection may as well have not been worn at all”

Smart hearing protection, however, utilises integrated microphones and data transfer to monitor and provide alerts related to wear rates and noise exposure. By utilising this type of insight from smart hearing protection, a hearing health professional or other duty holder can take action years before permanent harm is caused. This may involve educating and informing a person about their known sound exposures and taking steps to prevent exposures from occurring. The insights from smart hearing protection can provide the missing link between applying a process of continuous improvement with the hierarchy of risk controls (Figure 1).

Figure 1. Data and insights from smart hearing protection provide the missing link between

applying a process of continuous improvement to the effective use of the hierarchy of risk controls.

Further, smart hearing protection will typically also have ‘hear-through’ functionality, whereby the hearing protection incorporates speakers and microphones that accurately and safely reproduce the sound from the surrounding worksite, providing 360° situational awareness to the wearer.

There is a broad range of additional novel benefits that come from using the data provided by smart hearing protection. They include:

- Tracking hearing protection wear rates and improving them.

- Guaranteeing the effectiveness of the hearing protection provided by keeping track of worker’s personal exposure to noise and enabling intervention where required before permanent harm occurs.

- Improving site safety by replacing the ‘blindfold’ effect of traditional hearing protection with improved situational awareness.

- Removing hazards at source by using the data from the smart hearing protection to uncover and control unexpected noise hazards.

- Accurately assessing noise risks using a complete and continuous data source, removing the need to rely on assumptions and snapshots of risk.

While there is still a long way to go before no one is required to work in a noisy environment that is harmful to health, we must ensure that we are providing protection that truly works. This is the only short-term solution we have to knowingly stem the flow of harm being caused to millions of people every day while more robust long-term solutions to eliminate the noise hazard all together can be implemented.

Smart hearing protection worn by operatives at risk of noise exposure transmits valuable data and insights for viewing via a cloud-based platform. A duty holder is able to remotely review PPE wear-rates, noise exposure occurrences, noise levels and noise dose. The data and analytics enable highly effective risk assessment and risk management thanks to the focus on leading indicators of ONIHL and tinnitus.

Smart hearing protection should not be used in isolation. A complete solution to the existing noise exposure challenges and the high rates of ONIHL and tinnitus requires implementation of: 1) noise control solutions at source; 2) appropriate health surveillance; and 3) use of the data and insight provided by smart hearing protection.

If you work in the field of audiology or ENT, you are fortunate to have regular touchpoints with the population at risk of ONIHL and tinnitus. Your clinic is where the opportunity to educate and change behaviours is possibly greatest, given the patients interaction with you is predicated on a concern for their hearing. Their visit to you may well be the earliest and best opportunity for them to learn about occupational noise exposure and to make the most of the data and insights offered by smart hearing protection, together bringing a new meaningful dimension to your practice.

References

1. Schneider E, Paoli P, Brun E. OSH in figures - Noise in figures; European Agency for Safety and Health at Work. 2006.

2. Nelson DI, Nelson RY, Concha-Barrientos M, Fingerhut M. The global burden of occupational noise-induced hearing loss. Am J Ind Med 2005;48(6):446-58.

3. Health and Safety Executive. Final regulatory impact assessment of the control of noise at work regulations. 2005;9. www.hse.gov.uk/noise/noise.pdf

Further reading

1. The Control of Noise at Work Regulations 2005.

www.legislation.gov.uk/uksi/2005/1643/introduction

2. BOHS Midlands Webinar: Webinar: Has Noise Risk Reduction Failed? YouTube. 2022.

www.youtube.com/watch?v=a7pRA6PeV5I

All links last accessed May 2022.

Declaration of competing interests: DG is the Founder and CEO of Eartex Ltd, operating as Eave. Eave has developed the FocusLite smart hearing protection and Peak noise management system.